The story behind Bolwell and the Nagari

By Dave Carey | Photos: Shaun Tanner & SM Archives, 29 May 2019 Features

It's been 50 years since the Ford V8-powered Bolwell Nagari first stormed Aussie roads. Where did it come from? And where did it go?

BOLWELL. A small portion of you just read that word and thought: “Awesome.” But we reckon a larger portion thought: “Sorry, what?”

This article was first published in the May 2019 issue of Street Machine

That uncommon but seemingly innocuous surname is, for those in the know, synonymous with homegrown Aussie performance muscle. If you don’t know what we’re on about, grab a beer and read on. We’re going on a journey of discovery – in a V8 coupe built by a couple of blokes in a Melbourne shed.

That uncommon but seemingly innocuous surname is, for those in the know, synonymous with homegrown Aussie performance muscle. If you don’t know what we’re on about, grab a beer and read on. We’re going on a journey of discovery – in a V8 coupe built by a couple of blokes in a Melbourne shed.

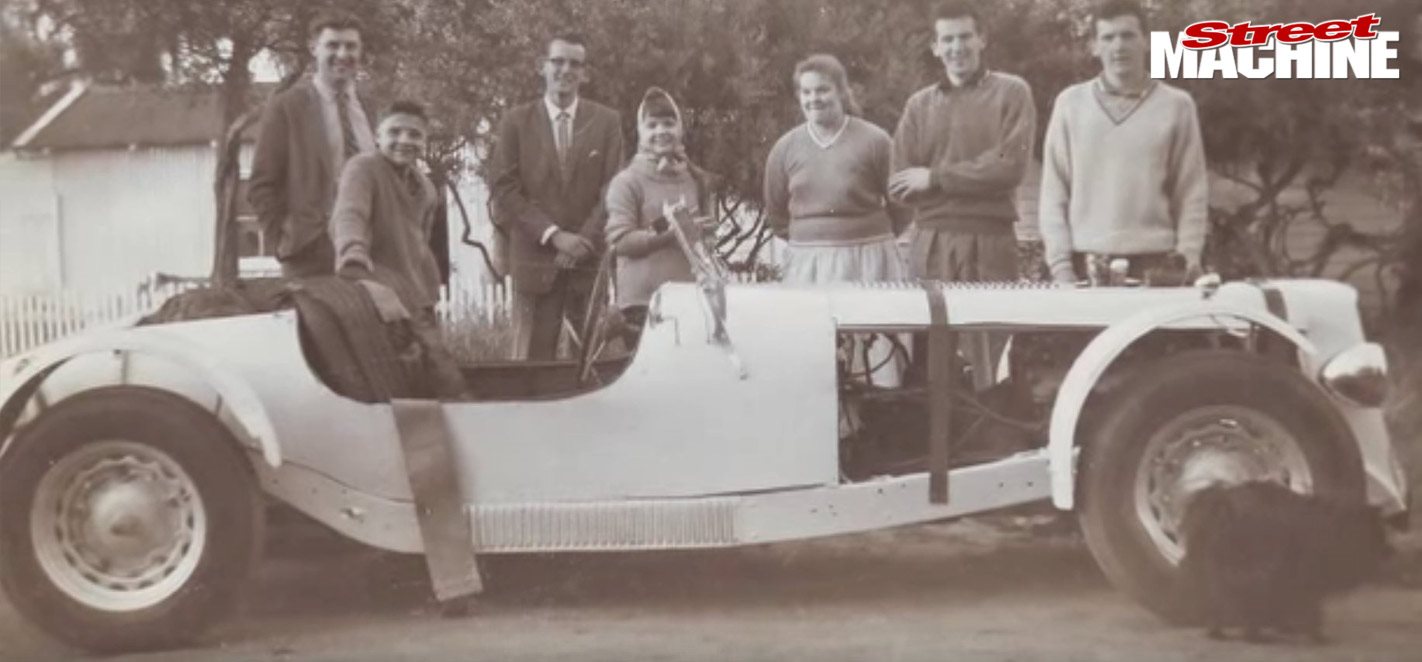

We catch up with company founder Campbell Bolwell at the Phillip Island Classic Festival Of Motorsport, where we find his nature affable and his enthusiasm for the cars that bear his name justifiably strong. Campbell makes no secret of the fact he got into the car-building industry literally by accident, though.

“I’d bought this 1937 Ford sedan and when I was away, my younger brother Graeme ‘borrowed it’,” he says. “He was 15 at the time, and loaded it with mates full of testosterone and took it out to the pine forest south of Frankston.” A wry smile creeps across Campbell’s face. “It came back in a very poor state. He wouldn’t look me in the eye when I got home. ‘Oh shit,’ I thought. It was unrecognisable.”

Read next: Home-built 2016 Ford GT40 replica

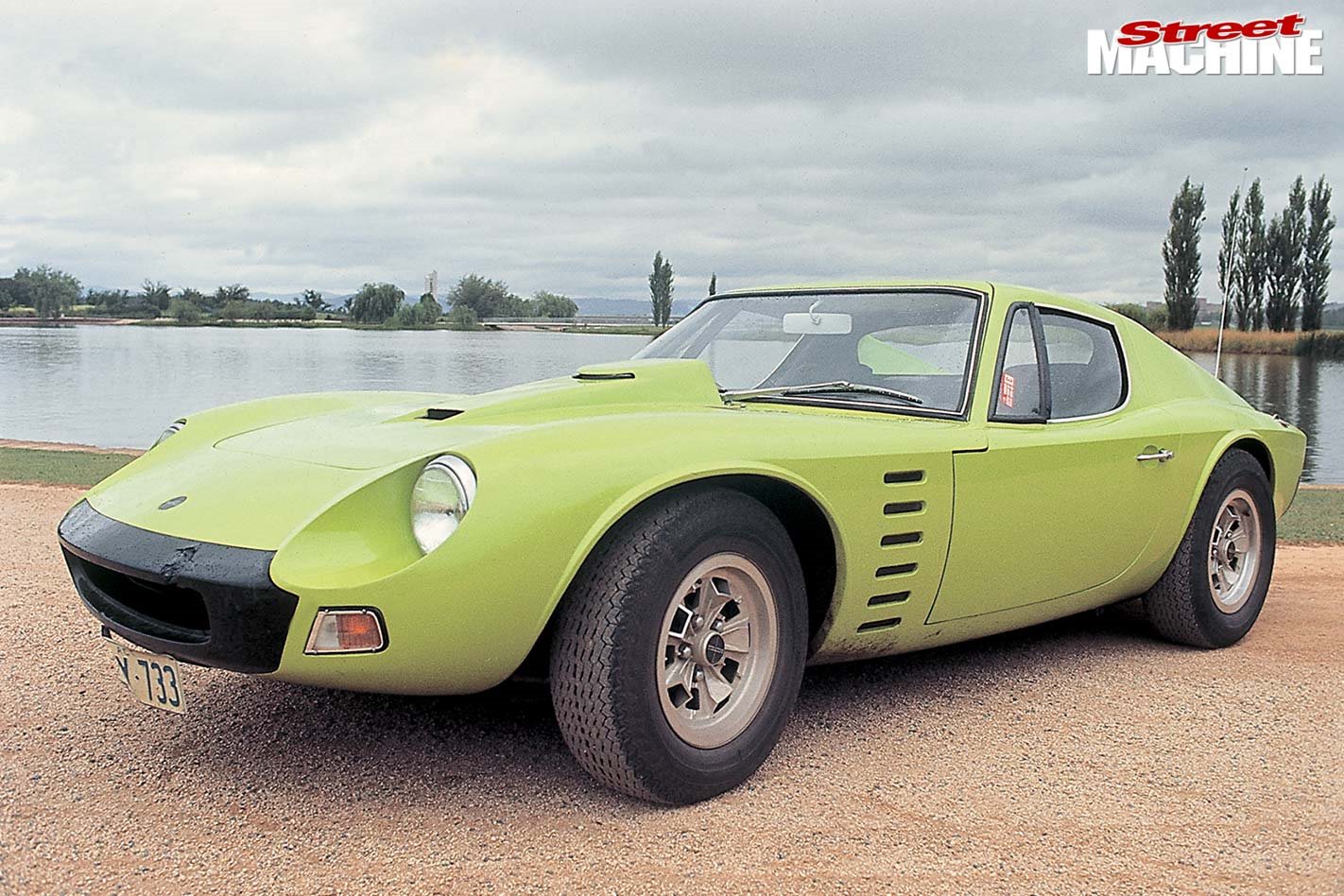

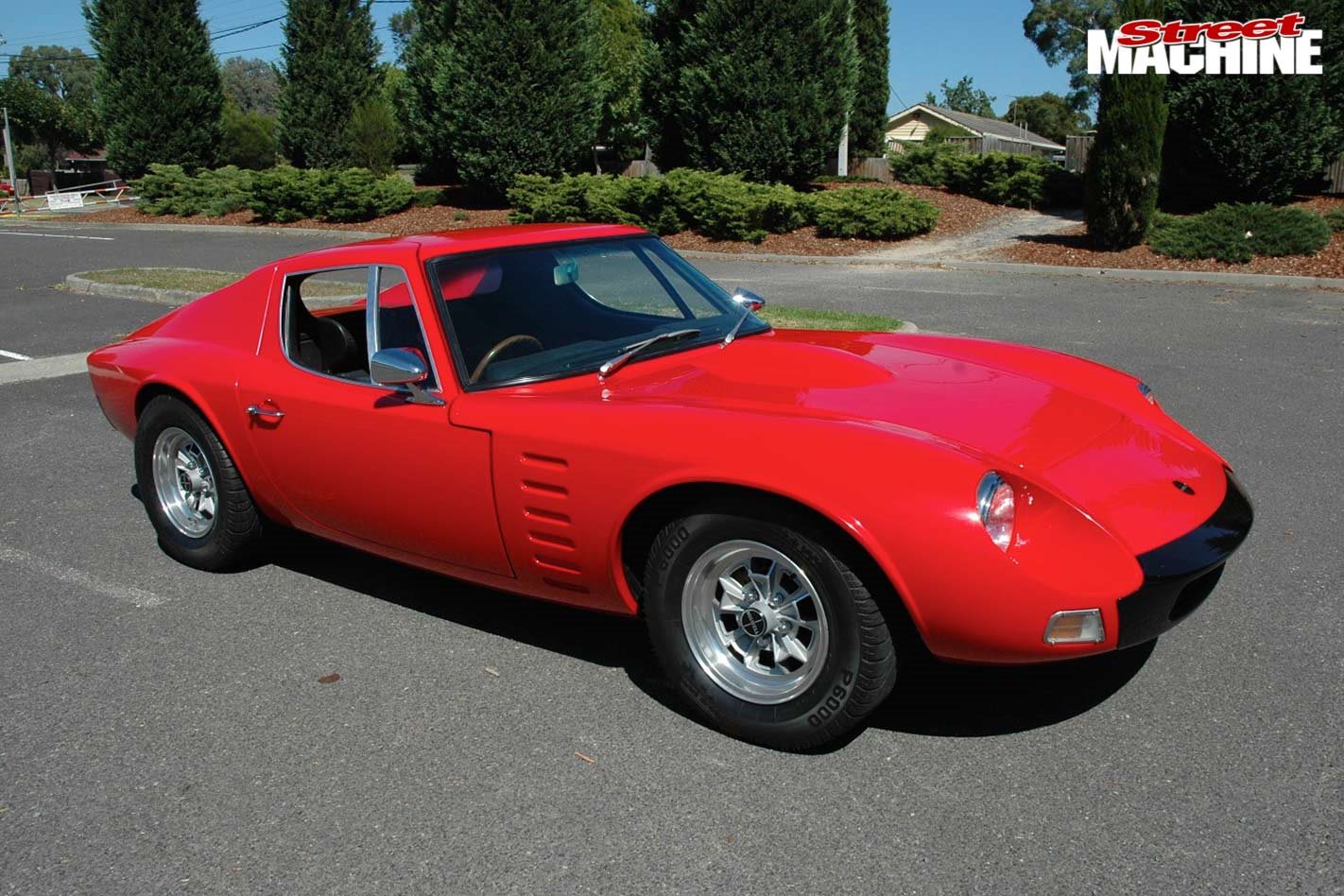

The Mk VII Bowell was a stunner and used HD-HR Holden parts for mechanicals, including the front suspension, diff, disc brakes and engine. Other bits included a Triumph four-speed, Austin 1800 steering and Toyota Crown tail-lights

The Mk VII Bowell was a stunner and used HD-HR Holden parts for mechanicals, including the front suspension, diff, disc brakes and engine. Other bits included a Triumph four-speed, Austin 1800 steering and Toyota Crown tail-lights

Returning the Ford to the road became a passion for 16-year-old Campbell. “I used to wag school to work on it,” he says. “But that’s what got me started. With a flathead V8 and lightweight bodywork, that car became the Mk I Bolwell. It beat the Healeys of the day, which was very satisfying.”

Although happy with how his Ford-based special turned out, Campbell wasn’t ready to go back to school just yet. “I thought that I could probably do better, so I built another car.” The Bolwell Mk II was based on an MG chassis and powered by a tiny but tuneable 1200cc Ford Ten four-cylinder, and was faster than the first car, despite the horsepower deficit. “Traction was always a problem with the Mk I,” Campbell says with a chuckle.

Read more: The story behind the HSV W427

Not one but two Mk IIIs followed, one built by Graeme and another by elder brother Winston. Each car ran a Jaguar engine on an Austin-Healey chassis, with the brothers both pioneering the use of fibreglass. The relatively new technology became the basis of the first commercially available Bolwell, the Mk IV, sold in kit form from 1963. Owners could build their cars up as desired, but most contained regular fare for the era: a Cortina/Anglia four-banger, a Standard rear end and Triumph Herald front suspension, brakes and steering. Fifty kits were sold, mainly roadster bodies, with the gull-winged coupe version accounting for 12 examples.

Not one but two Mk IIIs followed, one built by Graeme and another by elder brother Winston. Each car ran a Jaguar engine on an Austin-Healey chassis, with the brothers both pioneering the use of fibreglass. The relatively new technology became the basis of the first commercially available Bolwell, the Mk IV, sold in kit form from 1963. Owners could build their cars up as desired, but most contained regular fare for the era: a Cortina/Anglia four-banger, a Standard rear end and Triumph Herald front suspension, brakes and steering. Fifty kits were sold, mainly roadster bodies, with the gull-winged coupe version accounting for 12 examples.

The Mk V, sold from 1964, can certainly be seen as the predecessor to the famous Mk VII, with a long bonnet packing straight-six Holden power. “People used to spend a lot of money getting their Holden engines moving, but the bodies would rust out,” Campbell explains. “It was a commercial decision to go Holden on the Mk V and Mk VII; it gave them a home for their mechanicals.”

Legendary Wheels editor Peter Robinson recalls taking a Nagari and a GT Falcon through a favourite slice of road: “Out, back and around, hard on the brakes, down on cog, tail out, power still on, a genuine no-nonsense power drift, a curse at the low-geared steering, increasing heartbeat, sweat on the brow and the beat of two V8s trumpeting a message of supremacy across the land”

Legendary Wheels editor Peter Robinson recalls taking a Nagari and a GT Falcon through a favourite slice of road: “Out, back and around, hard on the brakes, down on cog, tail out, power still on, a genuine no-nonsense power drift, a curse at the low-geared steering, increasing heartbeat, sweat on the brow and the beat of two V8s trumpeting a message of supremacy across the land”

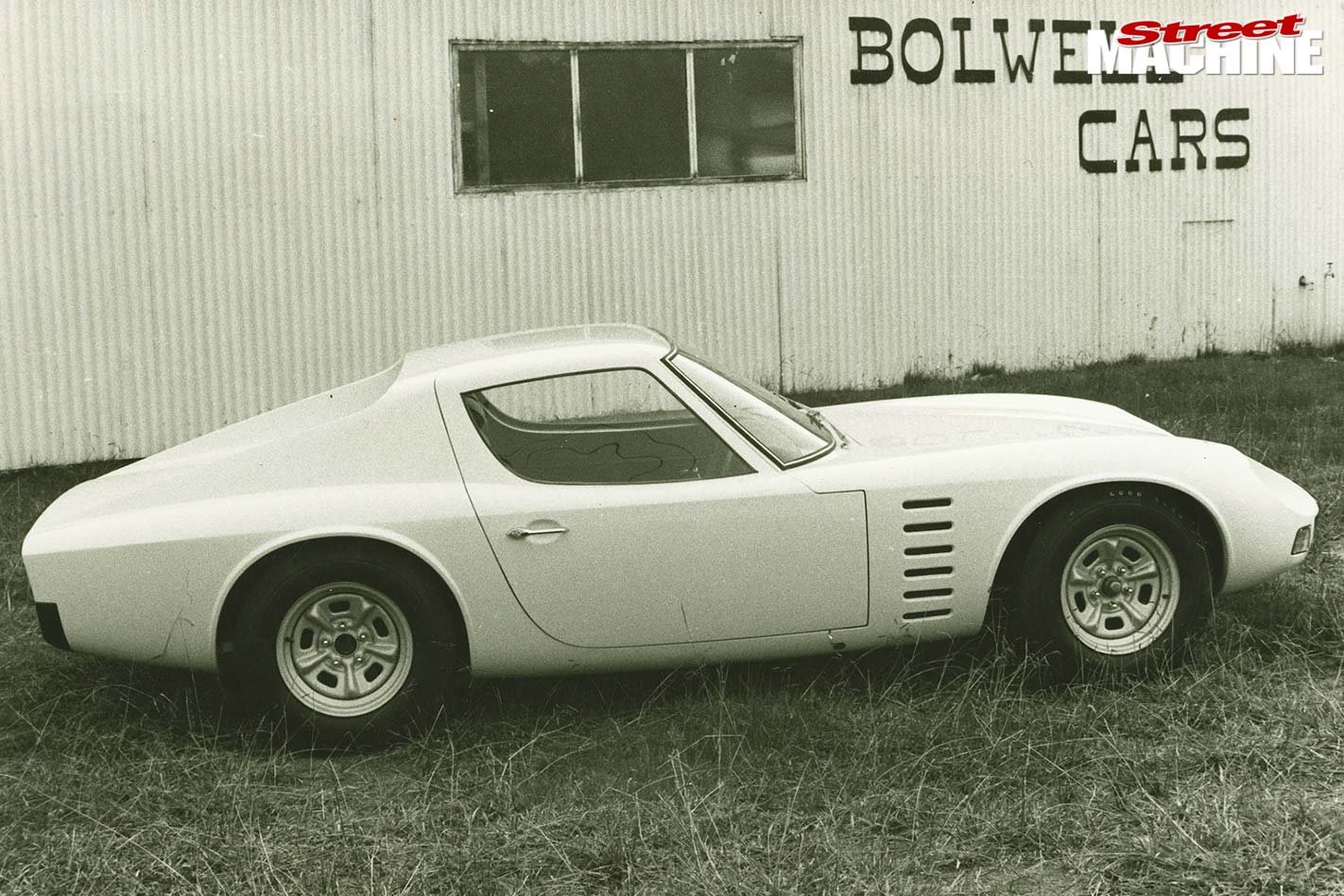

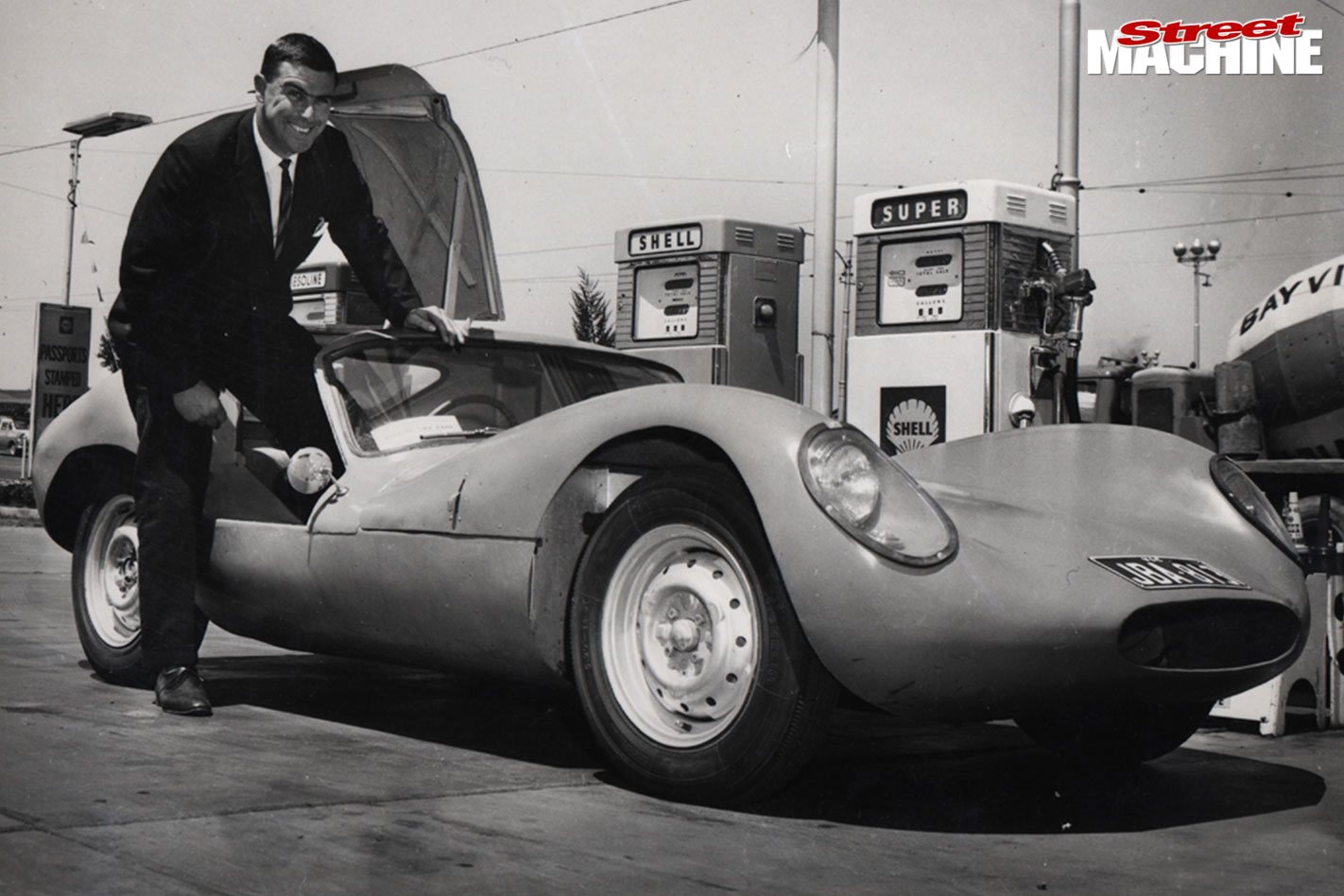

Bolwell stepped out on a limb for the Mk VI (aka SR6), with a mid-mounted Holden six and a VW gearbox. Designed primarily as a race car, the intention was to build more than one, but only the prototype was completed. Stepping back to a simpler front-engine design for the Mk VII, Campbell and his staff developed a brilliant sports car body with styling to rival the European coupes of the day. The Mk VII was a stunner, attracted a lot of media attention and shifted plenty of units.

“My brother Graeme went to work for Lotus for six months,” Campbell says. “He was on the development team for the Indianapolis race car and worked on the Europa. There were only four blokes in the department there and owner Colin Chapman was always hovering around. He loved Aussies; don’t ask me why. I guess we’re just an innovative species! Graeme returned with a wealth of knowledge. That’s when we built the Nagari.”

“My brother Graeme went to work for Lotus for six months,” Campbell says. “He was on the development team for the Indianapolis race car and worked on the Europa. There were only four blokes in the department there and owner Colin Chapman was always hovering around. He loved Aussies; don’t ask me why. I guess we’re just an innovative species! Graeme returned with a wealth of knowledge. That’s when we built the Nagari.”

The styling for the Mk VIII Nagari was an evolution of the Mk VII, but it’s fair to say that the Nagari represents the pinnacle of the Bolwell brand, certainly up to that point. “It was a team effort between my brothers, myself and my neighbour Ross McConnell,” Campbell says. “He still works for me even now; I mean, he’s retired, but you can’t get rid of these guys.

“My brother Winston was brilliant with his hands; he was a gold and silversmithing teacher and his pioneering work with fibreglass really set the direction for the cars we built.”

“My brother Winston was brilliant with his hands; he was a gold and silversmithing teacher and his pioneering work with fibreglass really set the direction for the cars we built.”

Tragically, Winston died in a motor accident the same year the Nagari was released, so he was never able to enjoy the company’s success. “Incredible that the accident wasn’t his fault given the crazy things we did in our cars back then,” Campbell concludes, with a sigh of lament.

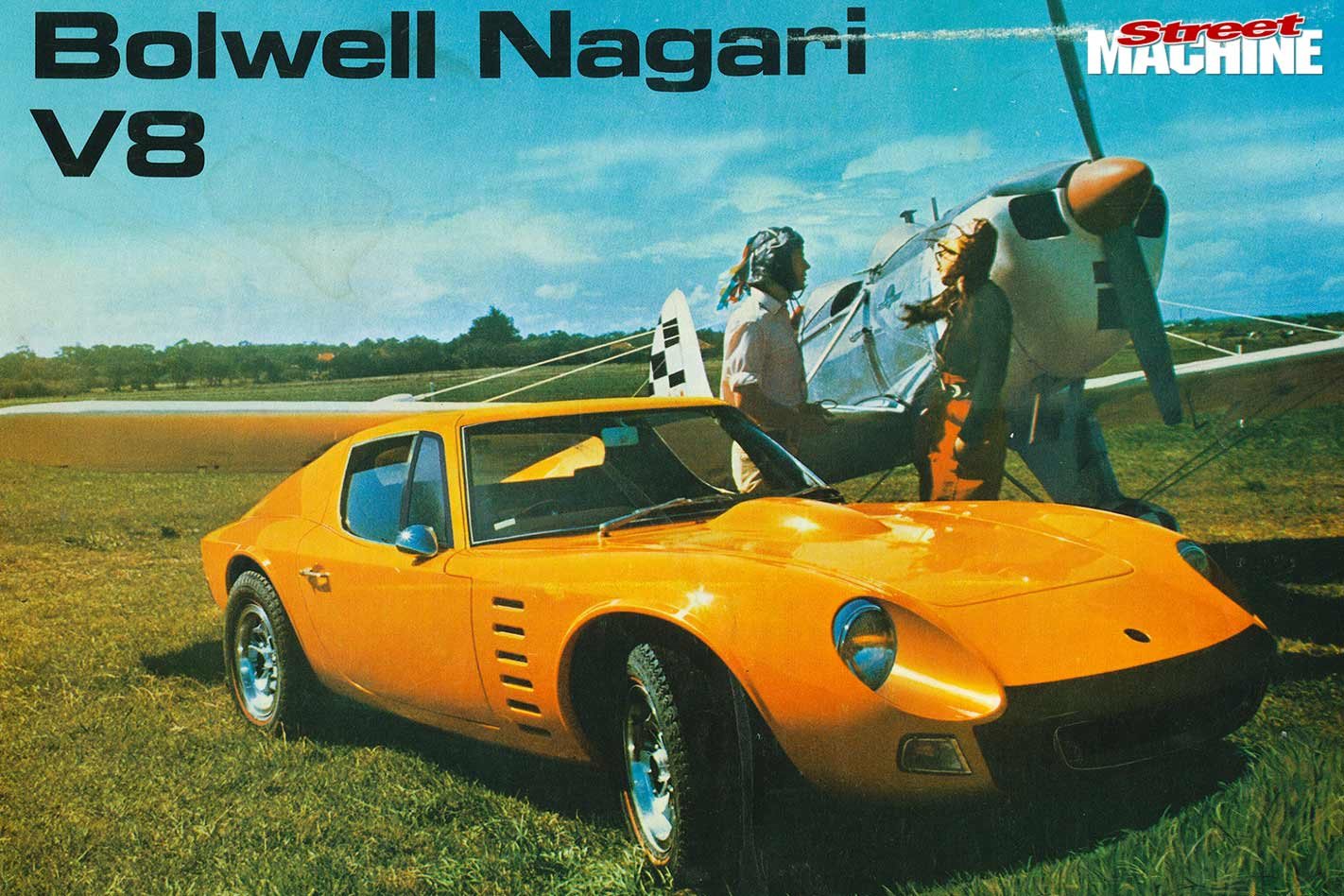

While the Nagari was a turn-key production car, it was born from the great Aussie tradition of specials and kit cars, which included the J&S Hunter, Purvis Eureka and Buchanan Cobra, amongst many others. The Nagari was the first of its kind to run a red-blooded V8 and is regarded as Australia’s finest homegrown sports car

While the Nagari was a turn-key production car, it was born from the great Aussie tradition of specials and kit cars, which included the J&S Hunter, Purvis Eureka and Buchanan Cobra, amongst many others. The Nagari was the first of its kind to run a red-blooded V8 and is regarded as Australia’s finest homegrown sports car

The Nagari was Bolwell’s first attempt at creating a production-ready, turn-key car rather than a kit, something facilitated by a good relationship with Ford Australia. Bespoke wishbones were attached to Falcon uprights, shockers, coil springs and sway-bars, along with front brakes and the entire rear axle assembly. All this gear hung off the Nagari’s sheet-metal backbone chassis, which was draped in the spectacular fibreglass sports-car body that gave the car its name: Nagari, meaning ‘flowing’.

The 302ci Windsor V8 up front could propel the Nagari to 100mph in 17.9 seconds and cut the quarter-mile in a reasonable 14.8. With modifications to the chassis, later 351 Cleveland cars would knock a second off the quarter-mile time, making for a true 13-second sports car; not bad for five decades ago. Production of the Nagari wound up in 1974, its discontinuation brought on by several factors: ADRs kept changing and increasing in complexity, manufacturing costs were creeping up and there was pressure on the brand to crash-test a car, something they simply couldn’t afford to do. Furthermore, the Nagari model was no longer ‘fresh’ and no replacement had been planned.

The 302ci Windsor V8 up front could propel the Nagari to 100mph in 17.9 seconds and cut the quarter-mile in a reasonable 14.8. With modifications to the chassis, later 351 Cleveland cars would knock a second off the quarter-mile time, making for a true 13-second sports car; not bad for five decades ago. Production of the Nagari wound up in 1974, its discontinuation brought on by several factors: ADRs kept changing and increasing in complexity, manufacturing costs were creeping up and there was pressure on the brand to crash-test a car, something they simply couldn’t afford to do. Furthermore, the Nagari model was no longer ‘fresh’ and no replacement had been planned. Campbell and Graeme Bolwell watch a crated Nagari being loaded for shipment to South Africa. A deal had been struck to manufacture and sell cars there under licence, but issues with South African legislation meant no cars were produced

Campbell and Graeme Bolwell watch a crated Nagari being loaded for shipment to South Africa. A deal had been struck to manufacture and sell cars there under licence, but issues with South African legislation meant no cars were produced

Rather than close the factory doors, Campbell and company chose to diversify, but the boss remains in awe of the dedication people still show towards his creations and to his brand. “I had no concept at all what the future would bring,” he says. “I was a petrolhead that failed high school, and from it all we’ve built up a multinational company.” Campbell speaks of their factory in Thailand plus the facility in Mordialloc, of truck cabs for Kenworth, electrical junction boxes for factories and turbines for wind farms. “All that was possible because of the reputation we forged building Bolwell motor cars,” he says.

“For an international company, our cars aren’t that well known outside of Australia. We were going to export to South Africa, but that didn’t happen. We also built a Nagari up in left-hand drive for the USA, but that bloke went broke!”

Around 128 Nagari coupes were built and about a dozen or so of the highly prized roadsters

Around 128 Nagari coupes were built and about a dozen or so of the highly prized roadsters

It’s rare that you can attend a car meet and chat to the founder of the company, so we press Campbell for more details about his own collection; did he keep any for himself? His eyes light up. “Yes! I built one up for myself, a convertible. My friend John Latham used to drive it to Calder, race it, then drive it home again!” he laughs. “We had an American PR guy, Gordon White, who borrowed it and loved it so much I didn’t see it for a year.” Campbell sold his Nagari when someone offered him stupid money for it, but he’s been buying some cars back of late. “We’ve got a Mk IV, a beautifully restored Mk VII, two Nagaris – a coupe and a convertible – one of the rear-engined Ikaras from 1980 and the prototype Mk X Nagari 300.”

Sales of the Mk X Nagari 300 have been disappointing, with only three cars finished since 2009 and two in partial stages of completion. The styling was an acquired taste and the powertrain from Toyota failed to stir any loins. Campbell then leans in: “But we’ve got something in the works,” he says with a wink. “Graeme and I are working on the brand-new Nagari 500.” He has my attention. “It’s got a 500hp 6.2-litre V8, is mid-engine, rear-wheel drive, and because it’s built using our vacuum-formed composite technology, it weighs less than a tonne.

Sales of the Mk X Nagari 300 have been disappointing, with only three cars finished since 2009 and two in partial stages of completion. The styling was an acquired taste and the powertrain from Toyota failed to stir any loins. Campbell then leans in: “But we’ve got something in the works,” he says with a wink. “Graeme and I are working on the brand-new Nagari 500.” He has my attention. “It’s got a 500hp 6.2-litre V8, is mid-engine, rear-wheel drive, and because it’s built using our vacuum-formed composite technology, it weighs less than a tonne.

“How much will it be? I don’t know. When can you have one? I don’t know that either. How fast will it be? I don’t know, but I’m sure it will move!”

Graeme and Campbell Bolwell pictured for the Wheels photoshoot documenting the launch of the 2009 Nagari 300. We’re pumped to see the 2019 version!

Graeme and Campbell Bolwell pictured for the Wheels photoshoot documenting the launch of the 2009 Nagari 300. We’re pumped to see the 2019 version!

Once a petrolhead, always a petrolhead! Not many guys can lay claim to developing their own car, under their own brand, building up a multinational company and still be kicking goals five decades later. Who said the Aussie V8 car is dead? It’s just waiting for someone like Campbell to come along with the enthusiasm of a man half his age to make it a reality. We can’t wait to see the new Nagari later this year, a fitting 50 years after the first. For more, just search Bolwell at whichcar.com.au/streetmachine.

BOLWELL TIMELINE:

1958: Bolwell MK I

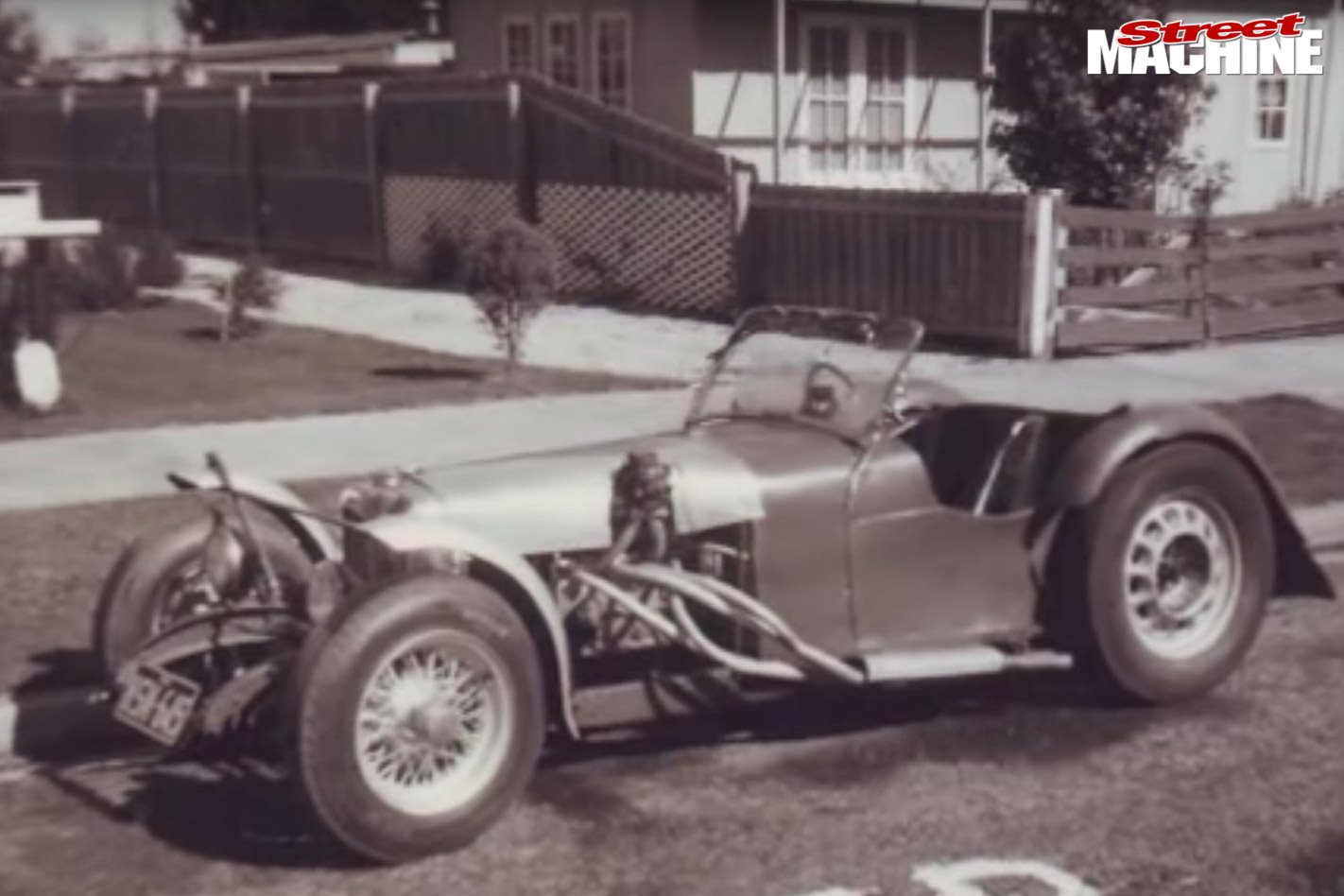

1958: Bolwell MK IBased on a 1937 Ford V8 sedan, with cycle guards, fold-down windscreen and bucket seats. Created after Graeme stacked his big brother Campbell’s car.

1960: Bolwell MK II

1960: Bolwell MK IIBased on an MG J2 chassis with a sidevalve Ford Ten 1200cc four-cylinder.

1962: Bolwell MK III

1962: Bolwell MK IIITwo built. Graeme’s car was built by, then purchased from, his dentist. Running a Jaguar motor on a Healey chassis, it was fitted with Bolwell’s first fibreglass body, designed and constructed by Graeme. Winston’s car was converted from an Austin-Healey 100/4 and also fitted with a Jaguar six-cylinder engine. Winston built and fitted a Maserati 300S-style fibreglass front and hardtop to the existing Healey bodywork.

1963: Bolwell MK IV

1963: Bolwell MK IVThe first commercially available Bolwell kit, based on a spaceframe chassis and fibreglass body with Ford ‘Kent’ motor as the intended powerplant. Around 50 sold; 12 hardtops, the rest roadsters.

1964: Bolwell MK V

1964: Bolwell MK VLarger, longer GT-like sports car kit designed for Holden grey motor and mechanicals. Large Perspex rear window, but early Mk VII DNA evident. Around 75 kits sold.

1967: Bolwell MK VII

1967: Bolwell MK VIIMore cohesively styled than predecessors, attached to a steel backbone chassis. Intended for Holden red six and period Holden mechanicals, 400 were sold until 1972.

1969: Bolwell MK VI

1969: Bolwell MK VIMid-engined with a tubular spaceframe and a modified Mk IV body, the ‘Bolwell SR6’ was intended as a production race car and first hit the track in November 1969. Only one was built.

Bolwell VK VIII Nagari

Bolwell VK VIII NagariThe legend, powered by brand-new Ford Windsor V8s and backed by a four-speed manual. The first 19 were turn-key vehicles, although kits of various levels of completeness were also available. Later chassis significantly modified to accept the Cleveland V8, with the 351 becoming an option. Ceased production in 1974 after 118 built. Bolwell Industries continued, becoming world leaders in the field of fibreglass and composite materials.

1980: Bolwell Ikara

1980: Bolwell IkaraBack-to-basics kit car with Volkswagen Golf mechanicals and unique ‘function before fashion’ body over a spaceframe chassis. Several novel fibreglassing techniques showcased. Twelve kits made before the concept was sold to a Greek manufacturer.

2009: Bolwell Mk X

2009: Bolwell Mk XBespoke vehicle running a mid-mounted supercharged Toyota Aurion V6 in a carbonfibre tub and carbon-reinforced composite body. Five cars built, but only three completed.

2019: Bolwell Mk X1

All-new car due for release later in the year, running a mid-mounted 500hp 6.2-litre V8.

All-new car due for release later in the year, running a mid-mounted 500hp 6.2-litre V8.

BOLWELL OWNERS:

Vic Garra

1972 Bolwell Nagari

1972 Bolwell Nagari

“WHEN I was young, I wanted a Ferrari, but when you get older you realise you can’t afford one. These look like a Ferrari and I figured the Ford running gear would be inexpensive to maintain. It was fitted with a Windsor when I bought it 20 years ago, but now it has a 351 Cleveland with alloy heads and is pretty similar to Phase III-spec, cam-wise. It’s got about 226kW at the rear wheels and is around the weight of an original MX-5, so it goes fairly well.”

“WHEN I was young, I wanted a Ferrari, but when you get older you realise you can’t afford one. These look like a Ferrari and I figured the Ford running gear would be inexpensive to maintain. It was fitted with a Windsor when I bought it 20 years ago, but now it has a 351 Cleveland with alloy heads and is pretty similar to Phase III-spec, cam-wise. It’s got about 226kW at the rear wheels and is around the weight of an original MX-5, so it goes fairly well.”

Darren Mason

1970 Bolwell Mk VII

1970 Bolwell Mk VII

“I WAS looking for an XU-1 Torana when I saw this Mk VII for sale. According to my partner, I was drooling over it. I’d only heard of the Nagari before then. Mine is running a 202 red six with triple Webers and a Celica five-speed, built by Ian Tate, the HDT chief mechanic who did Brock’s XU-1 race motors. I’ve done some mechanical and engineering work to it, but it’s mostly as-is, including those Halibrand wheels; they’re part of the reason I love the car. I think the Mk VII is one of the best-looking cars ever made in Australia.”

“I WAS looking for an XU-1 Torana when I saw this Mk VII for sale. According to my partner, I was drooling over it. I’d only heard of the Nagari before then. Mine is running a 202 red six with triple Webers and a Celica five-speed, built by Ian Tate, the HDT chief mechanic who did Brock’s XU-1 race motors. I’ve done some mechanical and engineering work to it, but it’s mostly as-is, including those Halibrand wheels; they’re part of the reason I love the car. I think the Mk VII is one of the best-looking cars ever made in Australia.”

Mike Julien

1970 Bolwell Mk VII

1970 Bolwell Mk VII

“I WAS 15 years old when my brother purchased a Bolwell race car; I fell in love the moment he took me for a ride. I was 20 when I bought my Mk VII. It had been smashed, so I rebuilt it and put it back on the road. My Mk VII was running a Buick V6, but I swapped it for a supercharged Ecotec. It’s got Commodore air con, disc brakes and power steering. I painted it in 1992, and put the carbonfibre wrap over the top recently for something different. It remains a work-in-progress; I don’t want it to get stuck in a shed, never coming out again. It was a three-week round trip to get from WA to Phillip Island, the Australian Grand Prix, then back again.”

“I WAS 15 years old when my brother purchased a Bolwell race car; I fell in love the moment he took me for a ride. I was 20 when I bought my Mk VII. It had been smashed, so I rebuilt it and put it back on the road. My Mk VII was running a Buick V6, but I swapped it for a supercharged Ecotec. It’s got Commodore air con, disc brakes and power steering. I painted it in 1992, and put the carbonfibre wrap over the top recently for something different. It remains a work-in-progress; I don’t want it to get stuck in a shed, never coming out again. It was a three-week round trip to get from WA to Phillip Island, the Australian Grand Prix, then back again.”

Campbell Bolwell

1969 Bolwell Mk VII

1969 Bolwell Mk VII

“We ended up without any of our own cars, because we sold them all. Lately we’ve been buying some back, usually at considerably more than what we sold them for.

“We ended up without any of our own cars, because we sold them all. Lately we’ve been buying some back, usually at considerably more than what we sold them for.

“Our Mark VII had quite a few owners before it came back; it was partially restored when we got it. Ross McConnell worked for the Healey factory for 25 years, so he undertook restoring the Mark VII on behalf of the Bolwell company while he was still there. They did all the bodywork and assembled the whole car.

“The flow-through isn’t all that wonderful, so they certainly benefit from a good heater and air con system, which this one has. Original Mark VIIs did not have a rear hatch, but one of our former employees developed a hatch conversion that a lot of people retrofitted. Aside from the hatch, it’s an original-looking car with period Dragway Splatts and a Holden 202 with triple SU carburettors, but it has got a Celica five-speed. You can’t tell it’s there and it’s just better to drive that way.”

Bill Tymms

Bolwell Nagari and more!

Bolwell Nagari and more!

“MY FIRST car was a Nagari; I bought it when I was 20 years old and thrashed it around for a few years. I currently own quite a few, including the only Mk VI. I picked it up in the 1990s with the intention of going racing, although it turned out that I couldn’t afford to, so I sold it. It went through a few owners until I bought it back a couple of years ago. It was built with a Repco-headed grey and a Volkswagen transaxle, but not long after was fitted with a hot red 186 and an open wheeler-style Hewland FT200 five-speed.

“MY FIRST car was a Nagari; I bought it when I was 20 years old and thrashed it around for a few years. I currently own quite a few, including the only Mk VI. I picked it up in the 1990s with the intention of going racing, although it turned out that I couldn’t afford to, so I sold it. It went through a few owners until I bought it back a couple of years ago. It was built with a Repco-headed grey and a Volkswagen transaxle, but not long after was fitted with a hot red 186 and an open wheeler-style Hewland FT200 five-speed.

“My Mk IV was built up by Campbell in 1963, but the buyer didn’t pay his bills, so they took the car back and sold it to Peter Mahoney. He ditched the Hillman Imp engine, installing a heavily modified Holden grey and four-speed Jaguar ’box. Peter raced it for years, selling it in about 1980. It was smashed almost immediately, so a decade later Peter bought it back. His son then raced it in Group M Historics. It’s been described as the most successful racing Bolwell.

“I own two Mk VIIs; one is an unrestored project, but the one here at Phillip Island I purchased because I love the history. Matt Pintar built it as a 202-powered production sports race car. It raced throughout the 1970s and into the 1980s; then Queenslander Barry Campbell purchased it and raced it. I restored it back to the Matt Pintar colour scheme; Grunt Performance handled the whole build in three months to get it here this weekend.”

Now get out and buy the Magazine for your library collection.

No comments:

Post a Comment